Automating system operation decision-making tasks with AI Determines whether engineers should be called --- Joint verification by Nihon Unisys and Hitachi

On April 5, 2018, Nihon Unisys and Hitachi, Ltd. (hereafter referred to as Hitachi) began joint verification of automating non-routine tasks that require human judgment in system operation with AI from April. announced.

Verification is performed in the production environment of the core system of a financial institution operated by Nihon Unisys, and machine-learned AI automatically determines whether it is necessary to call an engineer when a system warning message occurs. .

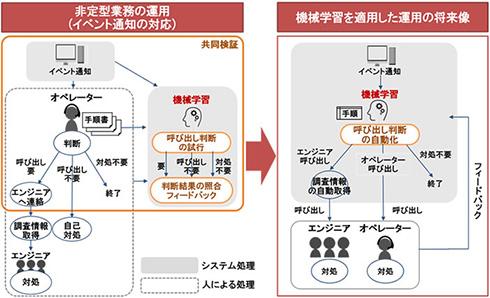

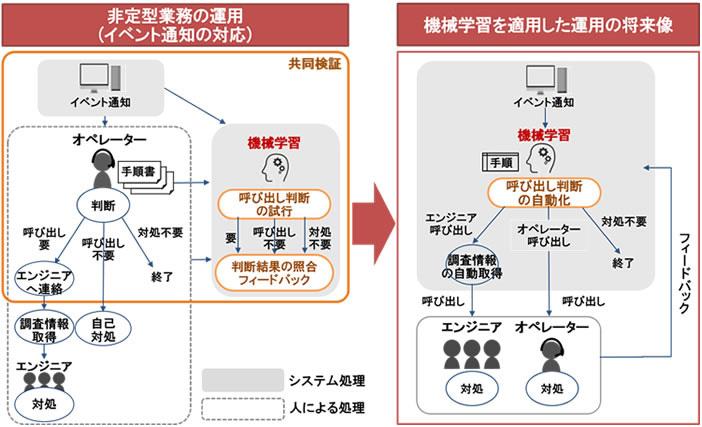

Image of application of machine learning to non-routine tasks of operators that require complex decisions Automated by machine learning parameter information and past response history. In addition, it continuously learns feedback from operators and engineers to improve judgment accuracy.

The AI operation platform is constructed by combining Hitachi's system operation management software "JP1" and AI, and uses machine learning technology based on OSS (open source software).

Prior to this verification, we conducted a pre-verification by comparing the results of operator's decision to call an engineer and the results of call decision by machine learning against the operation data of the platform layer for the past 3 months, and the result was the same. It was confirmed that

In this verification in the production environment, we will expand the monitoring range to the application layer and verify the automation of more complex decisions.

In addition, we will also conduct verification to automate the detection of failure signs, the isolation of problem areas during failure response, and the presentation of countermeasures. By setting monitoring items and optimal countermeasures for each factor based on past system performance failure information, the operating system can be monitored while comparing it with the state of normal operation that has been learned in advance, and signs of failure can be detected. It is said that

Through the verification, the two companies will also verify the effects of reducing operator workload and response time, and improving operational quality. By realizing operational automation in a system that operates 24 hours a day, it is possible to flexibly and efficiently consider operator assignments and working hours, leading to effective utilization of human resources.